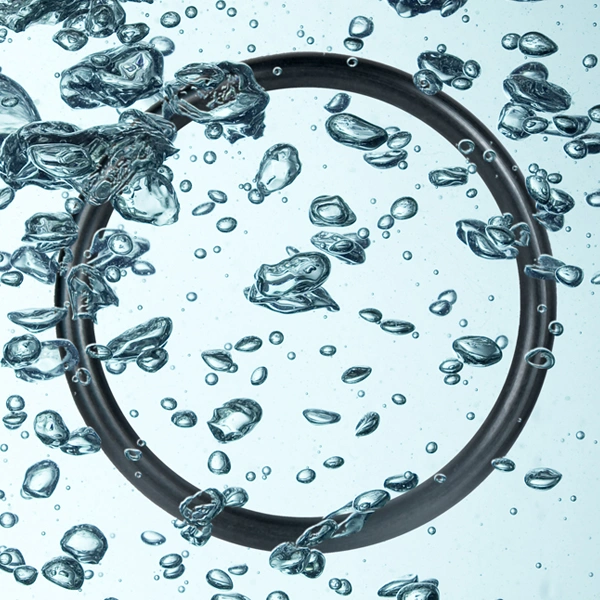

Chemraz® FFKM seals are found throughout a broad range of mission-critical equipment in key process areas of the world’s semiconductor fabs, including etch, deposition, aqueous, electro-chemical (electroplating), and more.

This site provides quick and easy access to Chemraz® semiconductor information – including interactive tools, technical resources and documents, seal training, the latest product news, and an elastomer selection guide – your one-stop shop for everything Chemraz®.

Interactive Tools

Elastomer Selection Guide

Enter your specific application criteria on the selection wheel and give it a spin for a Chemraz® seal material recommendation. Options include: Deposition, Etch, Aqueous, Subfab, & Electroplating.

O-Ring Analysis Tool

Use this tool for analyzing your current gland and o-ring combination. Modifications to the o-ring size recommended to optimize the users design to improve lifetime of seal. Please contact Greene Tweed engineering for help or advice if required as some applications are difficult to optimize both at ambient and operating temperatures.

Gland Size Calculator

Use this tool for designing new glands based upon desired o-ring sizing. Please contact Greene Tweed engineering for help or advice if required as some applications are difficult to optimize both at ambient and operating temperatures.

Services

Custom Gland Modeling Services

Instruction Guide: View our Instruction Guide for application instructions and physical properties information on Reprorubber® Putty and how to contact us for information and assistance.

Custom Seal Design

Greene Tweed’s many Chemraz® formulations are used by the world’s leading semiconductor fabs because of their superior performance and reliability.

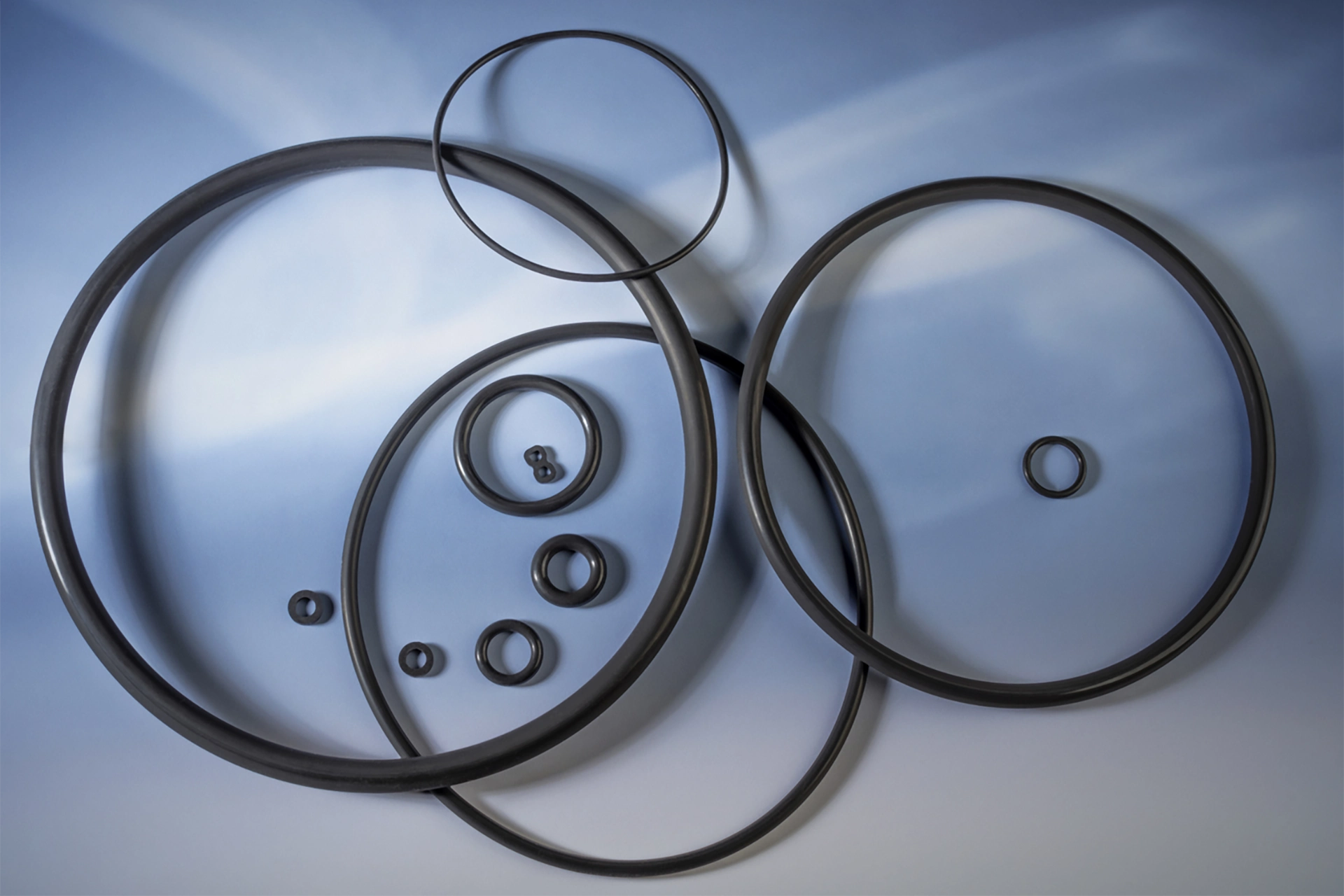

Sealing solutions manufactured from Chemraz® perfluoroelastomers (FFKM) provide customers with reduced downtime and maintenance costs. Our Chemraz® seals are found in a variety of semiconductor segments, including Aqueous, Deposition, Electroplating, Etch, and Subfab.

As a fully fluorinated elastomer, Chemraz® has the broadest chemical resistance of any elastomeric material, combining the resilience and sealing force of an elastomer with the chemical resistance approaching that of PTFE.

Chemraz®’s distinctive chemical composition makes it well suited for a range of applications. Because of its low compression set, outstanding physical properties, and universal chemical resistance, Chemraz® provides an incredibly reliable seal. Chemraz® o-rings, gaskets, and custom elastomeric shapes can withstand a wide range of temperatures (-40°F to 615°F/-40°C to 324°C).

Our Chemraz® portfolio of materials offers grades that can provide:

- Minimal extractable ion content

- Exceptional chemical resistance

- Low particle generation

- High dimensional stability

- Minimal metallic ion content

- Exceptional plasma resistance

With fully qualified engineering, sales, and support personnel located throughout the Americas, Europe, and Asia, Greene Tweed can recommend the Chemraz® sealing solution that best fits your application.

Finite Element Analysis

Let Greene Tweed analyze the relationship between your seal solution and hardware through Finite Element Analysis (FEA).

Greene Tweed uses FEA to quickly and accurately perform stress-strain and thermal analysis of complex structures.

FEA can be used to design new seals, improve existing seals, or determine the causes of seal failure, providing a simple method to graphically examine how a seal will function without the usual guesswork. By modeling a seal application on a computer, we can design the most effective solution to meet your particular sealing requirements.

Finite Element Analysis can:

• Optimize seal designs

• Minimize design time

• Identify high stress areas

• Reduce costs

Let Greene Tweed design the optimum Chemraz® solution for your application.

Gland Application Review

Ensure that you are getting the maximum seal performance for your application.

Greene Tweed engineers will review your application for stretch, fill, compression, and other properties.

Let Greene Tweed engineers review your application.

Send us the dimensions of your hardware/gland, and the seal geometry that you are currently using, and we will review your application for form, fit, and function.

Fill out the form along with any necessary details in the Comments field.

Click Submit and a Greene Tweed representative will contact you.

Seal Training Videos

Seal Geometry and Design

Seal Failure Analysis

Basics of Seal Handling and Installation

Basics of Seal Removal